Yihai Kerry actively advances sustainability and aligns with national climate policies. Our Sustainability Committee oversees climate-related risks and opportunities, driving emissions verification and low-carbon initiatives through green production, sustainable products, and industry collaboration to support Carbon Peak and Carbon Neutrality goals.

Amid growing global climate challenges, Yihai Kerry —subsidiary of a member of the UN Global Compact — has actively aligned with the Paris Agreement and national climate goals. In 2025, the company announced its 2050 net-zero roadmap, formalizing its commitment to achieve net-zero greenhouse gas emissions by mid-century. This strategy underscores collaboration with upstream and downstream partners to build a coordinated low-carbon value chain.

|

|

Enhancing Risk Response Capabilities

In 2023, to improve the capacity to address climate change, the Company has integrated climate change risks into overall risk assessment and management system. We have established a working mechanism, led by the Board of Directors, with the Sustainability Committee in charge and other relevant departments collaborating. Additionally, we follow the disclosure methodology and recommendations of the Task Force on Climate-related Financial Disclosures (TCFD) to conduct annual assessments of climate change risks, including physical and transitional risks, as well as opportunities. We are committed to developing comprehensive strategies for climate risk prevention and fully supporting global climate action.

Constructing a Low-Carbon Value Chain

Yihai Kerry Arawana is dedicated to constructing a green and low-carbon value chain. The Company assess the environmental impact of the products from a life cycle perspective, and work towards achieving national carbon peak and carbon neutrality goals to mitigate the impact of climate change.

Carbon Neutrality Factory

In 2022, Yihai Kerry successfully built the first "carbon neutrality factory" in the domestic cereal and oil industry, playing an essential role as a model to promote China's cereal and oil industry to achieve the goal of "carbon peaking and carbon neutrality".

In 2024, Yihai Kerry Qinhuangdao Jinhai Specialty Edible Oil Industry Co., Ltd, Yihai Kerry (Shijiazhuang) Food Industry Co., Ltd. and Yihai Kerry (Shijiazhuang) Buckwheat Products Co., Ltd. have successfully completed the 2023 Carbon Neutral Certification.

Up to now, four factories have been recognized as carbon neutral.

Product Carbon Footprint

Yihai Kerry implements energy saving and emission reduction efforts along the value chain by assessing greenhouse gas emissions in the supply chain. We continue to carry out carbon footprint verification of some of our core products and have obtained carbon footprint certificates for the relevant products.

GHG emissions reduction

We uphold the adoption of clean energy, promote resource recycling, and carry out energy conservation and emissions-reduction measures.

By the end of 2024, Yihai Kerry reduce GHG emissions by a total of 1,363,000tons of CO2e through the use of biomass energy (rice husks), biogas recycling, procurement of solar power, and energy-saving and emission reduction projects.

| Solar energy utilization |

Biomass energy utilization (rice husks) |

Methane recycling |

|

Yihai Kerry launched the construction of solarphotovoltaic power -generation facilities. By providing sites such as roofs of subsidiary factory buildings to professional institutions in order to lay solar panels and produce clean electricity, and adopting the mode of "Self-generation for self-use, surplus for the Grid", the proportion of renewable clean energy used by factories is increased and CO2 emission is reduced. |

To reduce fossil energy consumption,reduce GHG emissions, and ensure stable electricity supply, and steam and heat required for production, Yihai Kerry is promoting the use of rice husks.

|

By establishing biogas recycling facilities, Yihai Kerry has reduced GHG emissions caused by biogas generated in the factory's sewage treatment process.

The collected biogas is fed into the boiler to produce steam and reduce the consumption of coal or natural gas in the boiler, while the excess biogas is burned through a flare to ensure minimal leakage of methane. |

In addition, the Company promotes the green office concept by encouraging employees to use online conferencing to reduce GHG emissions generated by travel. Also, by using shared disks, servers and printing networks in office areas, we reduce the use of paper, thereby reducing GHG emissions in the office.

Internal storage and transportation

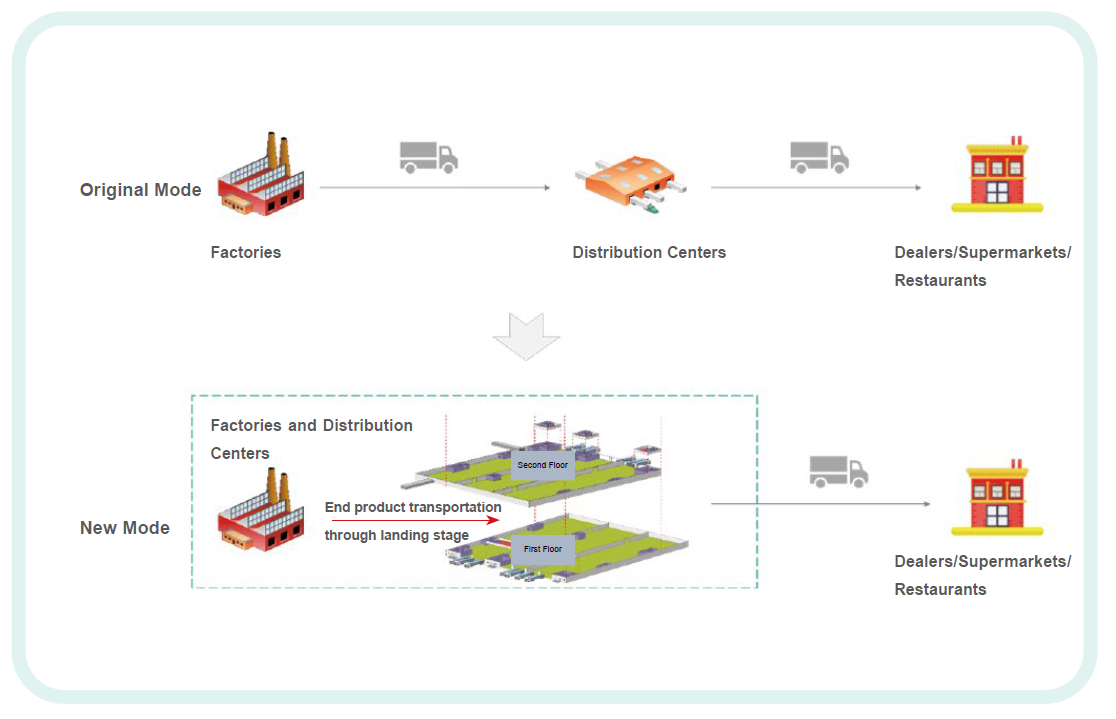

Yihai Kerry has adopted new models, new energy and new technologies to reduce direct GHG emissions in internal storage and logistics.

Upstream and downstream transport logistics

The Company cooperates with carriers to achieve the refined management of fuel in transportation through informationization and standardization. Besides, by optimizing routes and integrating resources to shorten the supply chain, thus effectively shortening the transportation distance and reducing waste, so that we reduce Scope 3 GHG emissions.

Upstream and downstream supply chain emissions-reduction action

In the upstream and downstream energy saving and emissions-reduction process, the Company provides assistance and cooperation for farmers and suppliers to reduce GHG emissions generated from the upstream supply chain's raw material cultivation, processing and production. We also reduce GHG emissions from the use of end product through product design and product packaging improvement action.

| Energy conservation and emissions- reduction action in raw material cultivation |

|

| Energy conservation and emissions- reduction action in supplier production and processing |

|

|

Energy conservation and emissions-reduction action in Product use |

|

Target:

Target: